Is SPC flooring suitable for underfloor heating rooms?

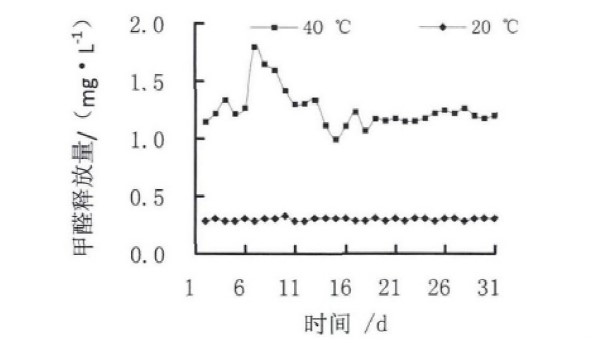

Usually, whether it is a new house renovation or an old house rebuilt, the main choices for flooring decoration are hardwood flooring, laminate flooring, vinyl flooring. Although most of the flooring products available for sale are FloorScore® or Green guard tested, they are mostly tested in a standard room temperature environment. However, the release of VOCs increases with increasing temperatures.

As underfloor heating is heated below the floor, there is a temperature difference between the front and back of the floor, which is more conducive to the release of VOCs than wall heating and air conditioning.

Dishover uses experimental data to show users how VOCs are released from hardwood flooring, laminate flooring and vinyl flooring when underfloor heating is used and the other effects of underfloor heating on the floor.

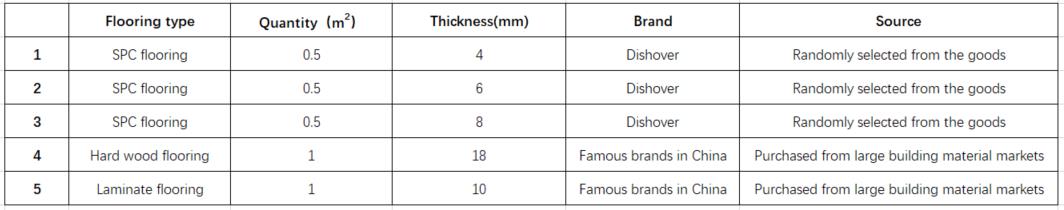

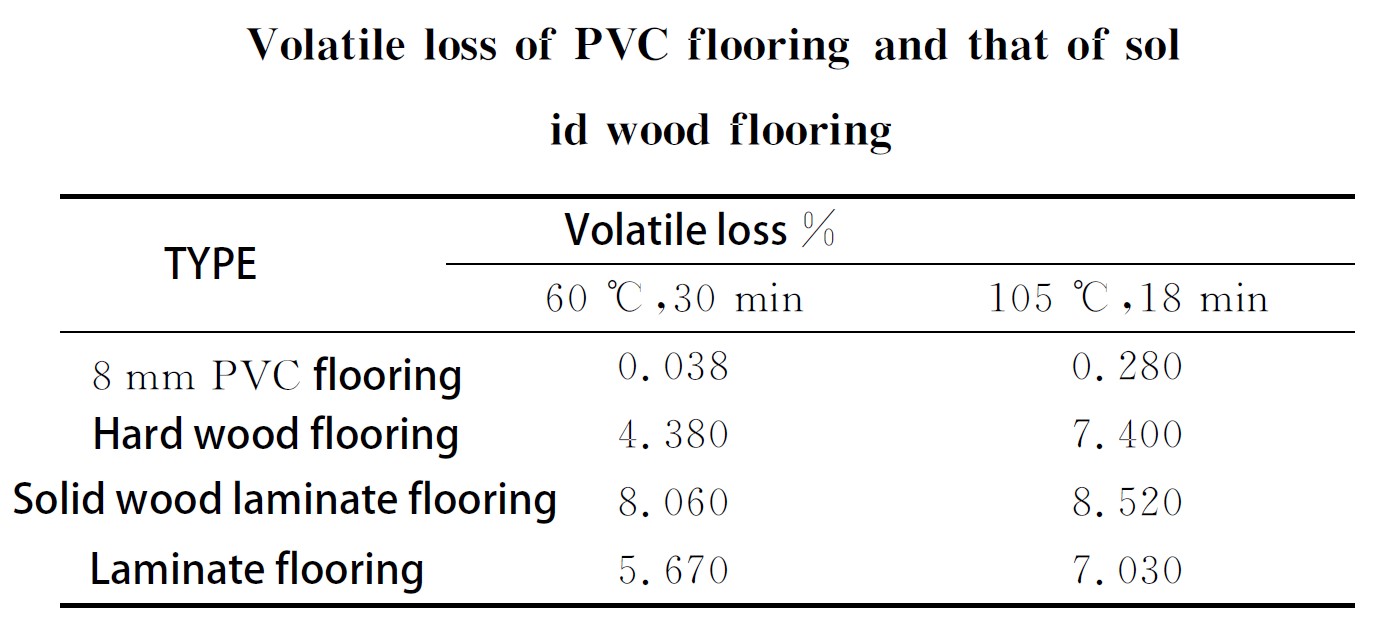

1.Test material

Dishover used its own production of SPC flooring and hardwood and laminate flooring from a major building materials market as test samples, see the table below for details. The samples are representative of the same grade of product and Dishover declined to disclose information on other brands.

2.Thermal conductivity test

The test sample is laid on a floor with underfloor heating and the surface temperature is measured at the same set temperature. The results are shown in the table below.

From the test results it can be concluded that the surface temperature decreases as the thickness of the floor increases. The SPC flooring has the best thermal conductivity probably due to the presence of stone dust. Hardwood flooring has the worst thermal conductivity due to its maximum thickness.

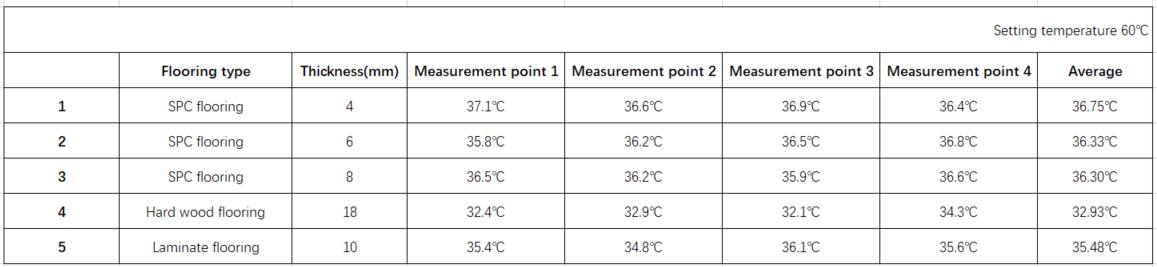

3.Effect of wear-resistant layer thickness on heat transfer

Temperature transfer tests were carried out using vinyl flooring with a thickness of 6mm and a wear layer thickness of 0.5mm and 0.7mm respectively, resulting in the following graph.

It can be seen that the thickness of the wear layer does not have a significant effect on the temperature transfer.

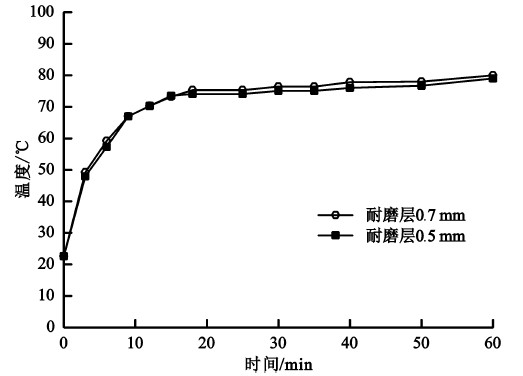

4.Measuring the rate of loss of volatile substances.

We use ISO1269:2006 GB/T2914-2008 “Plastics – Homopolymer and copolymer resins of vinyl chloride – Determination of volatile matter (including water)”. This means that the percentage of mass loss of the article under test at the specified time and temperature is expressed as a percentage.

The volatility of PVC flooring can be derived from the measurement results is much less than other flooring, which is generally understood to mean that solid wood flooring has a higher water content and needs to be used with a humidifier to balance the humidity when using underfloor heating to prevent the floor from deforming. However, the water content of solid wood laminate flooring and laminate flooring is lower and their volatilisation rate exceeds that of solid wood flooring at the same temperature, which indicates that solid wood laminate flooring and laminate flooring will release a large amount of volatile substances in a long-term heated environment and are not suitable for use in an underfloor heating environment. Several studies have shown that the release of formaldehyde increases significantly with increasing temperatures.

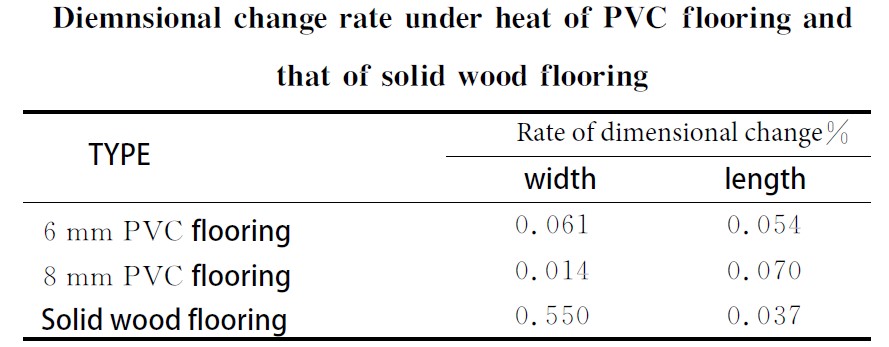

5.Dimensional stability

We tested the floor coverings in accordance with GB/T 34440-2017, ISO 10582:2017 “Resilient floor coverings – Heterogeneous poly(vinyl chloride) floor covering – Specifications Specifications”.

The specimens were left to stand at 80°C for 6 hours, cooled at room temperature for 24h and the specimen dimensions were measured. The following table shows the results.

It can be seen that the dimensional variation in PVC flooring is negligible. It is not surprising that the variation in solid wood flooring is greater.

So, when installing solid wood flooring in areas with large temperature differences, we recommend that users allow sufficient expansion joints to accommodate temperature changes. This prevents the floor from deforming.

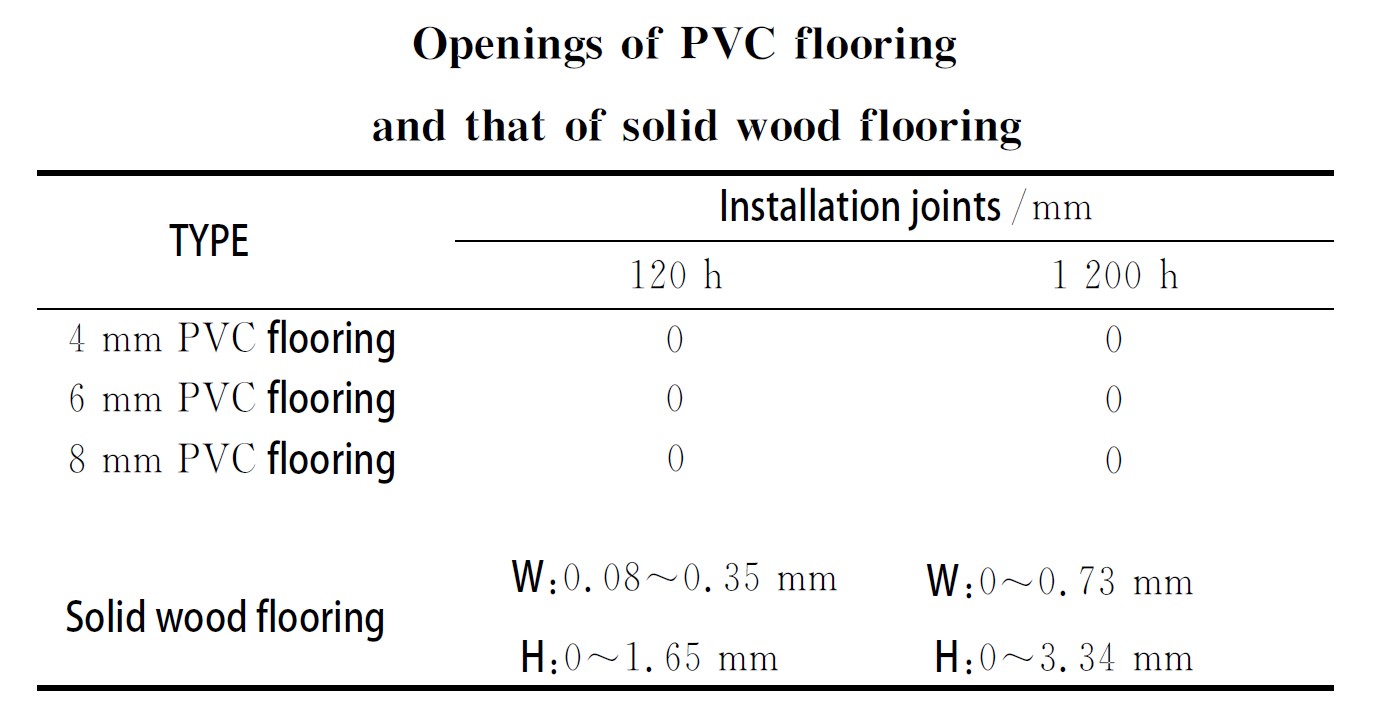

6.Installation joint deformation test

We measured the dimensions of the installation joints of flooring installed over underfloor heating using the feeler gauge, also according to the methods provided by GB/T 34440-2017,ISO 10582:2017. The following table was obtained.

It can be observed that Dishover’s SPC flooring does not deform in the installation joints when the underfloor heating temperature is set at 60 °C. This shows that Dishover’s SPC flooring has better thermal and dimensional stability for long-term use in underfloor heating environments.

Incidentally, SPC flooring manufactured by Dishover is sampled for high temperature deformation properties before it leave the factory.

7.Weathering performance test

The floor was cut to 50mmx120mm and placed in a UV weathering chamber with radiation energy of 0.89J/m2 and an irradiation temperature of 50°C. After 100h, the solid wood flooring showed obvious fading, while the colour of the SPC flooring did not change significantly.

Summary

- SPC flooring has significantly better thermal conductivity than solid wood flooring, reducing energy waste.

- SPC flooring VOC is less than solid wood flooring and laminate flooring, and does not contain formaldehyde, eco-friendly.

- SPC flooring dimensional stability is better than solid wood flooring, more suitable for underfloor heating environment use.

- SPC flooring’s weather resistance is better than solid wood flooring, suitable for long-term use of the environment using underfloor heating.